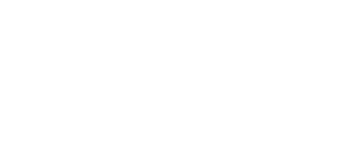

Facades are the face of a building. SNALCO manufactures robust aluminium sections for curtain walls and structural glazing. Our mullions and transoms are designed to withstand high wind pressure while supporting heavy glass panels.

SNALCO is a Manufacturer of premium aluminium facade sections. Glazing profiles, mullions, and transoms for high-rise building exteriors. In the dynamic world of architectural design and construction, facade sections represent more than just building exteriors—they’re a critical intersection of engineering, aesthetics, and performance. As a leading facade section aluminium extrusion manufacturer, SNALCO has been at the forefront of transforming architectural visions into tangible, high-performance realities.

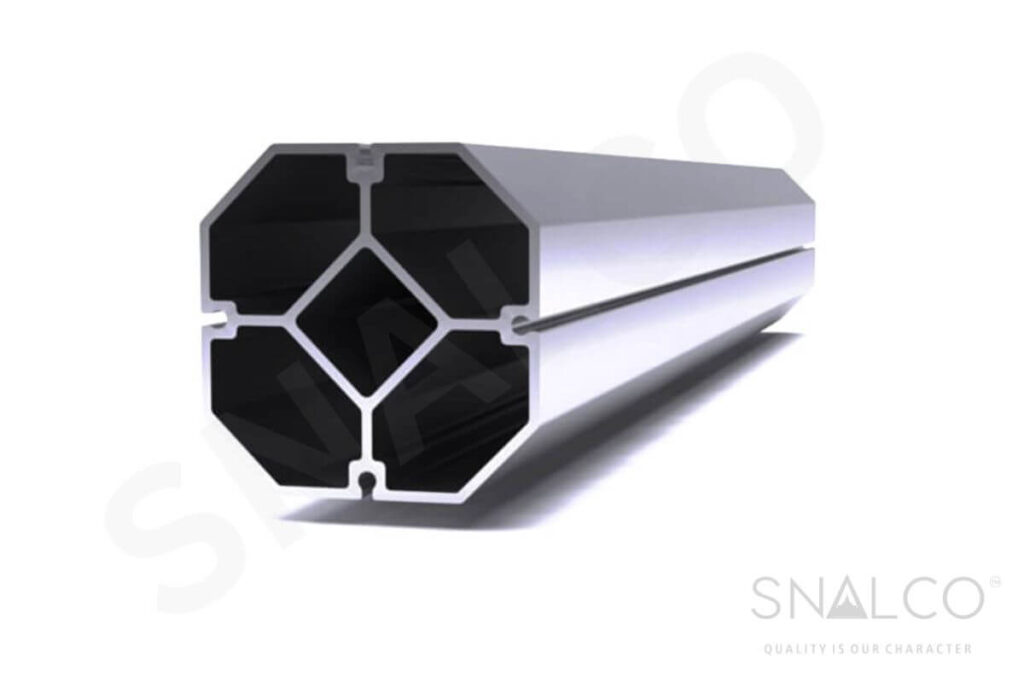

• Load Bearing: High I-value for structural stability

• Aesthetics: Sharp edges and consistent anodizing

• Integration: Compatible with major glazing systems

Alloy: 6063 T6

Finish: PVDF / Anodized

Depth: 50mm – 200mm

The Art and Science of Facade Section Aluminium Extrusion

Facade section manufacturing is a sophisticated process that demands exceptional precision, technical expertise, and innovative approach. At SNALCO, we’ve developed a comprehensive manufacturing strategy that goes beyond traditional extrusion techniques, delivering solutions that meet the most demanding architectural requirements.

Key Advantages of Our Facade Section Manufacturing

- Customized Profile Design: Each facade section is meticulously crafted to meet specific architectural specifications

- Advanced Material Engineering: Utilizing high-grade aluminium alloys for superior strength and durability

- Precision Manufacturing: State-of-the-art extrusion technologies ensuring consistent quality and performance

- Architectural Flexibility: Creating profiles that enable complex design possibilities

Our Facade Section Manufacturing Capabilities

Our facade section aluminium extrusion manufacturing process integrates cutting-edge technology with decades of engineering expertise. We understand that each project presents unique challenges, which is why we’ve developed a flexible, responsive manufacturing approach.

Architectural Applications

Facade sections manufactured by us find applications across diverse architectural environments:

- Commercial building exteriors

- High-rise residential complexes

- Institutional and educational facilities

- Sustainable green building projects

Connect with SNALCO

Interested in exploring how SNALCO can transform your architectural project? Reach out to our expert team for personalized consultation and detailed project discussions.