Unlocking the Engineering Marvel of Aluminium Extrusion in Construction

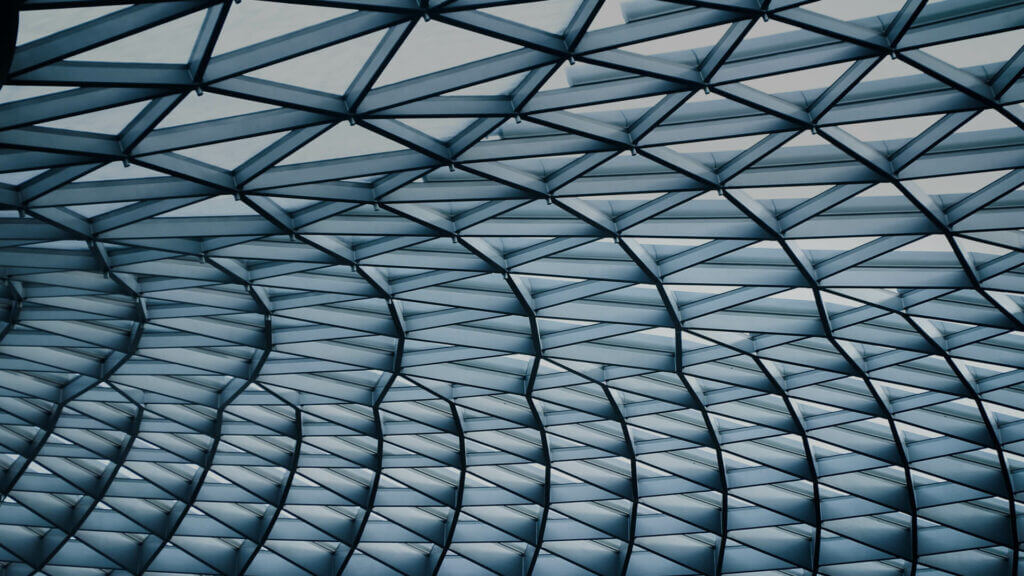

Imagine a material that can transform architectural dreams into reality – welcome to the world of building and construction aluminium extrusion! This incredible manufacturing process is revolutionizing how we design, build, and imagine structural solutions.

What Makes Aluminium Extrusion a Game-Changer for the Building & Construction Industry?

Key Advantages:

- Lightweight Strength: Incredible durability without the heavy weight

- Versatility: Endless design possibilities

- Corrosion Resistance: Built to last in any environment

- Sustainability: Eco-friendly material solution

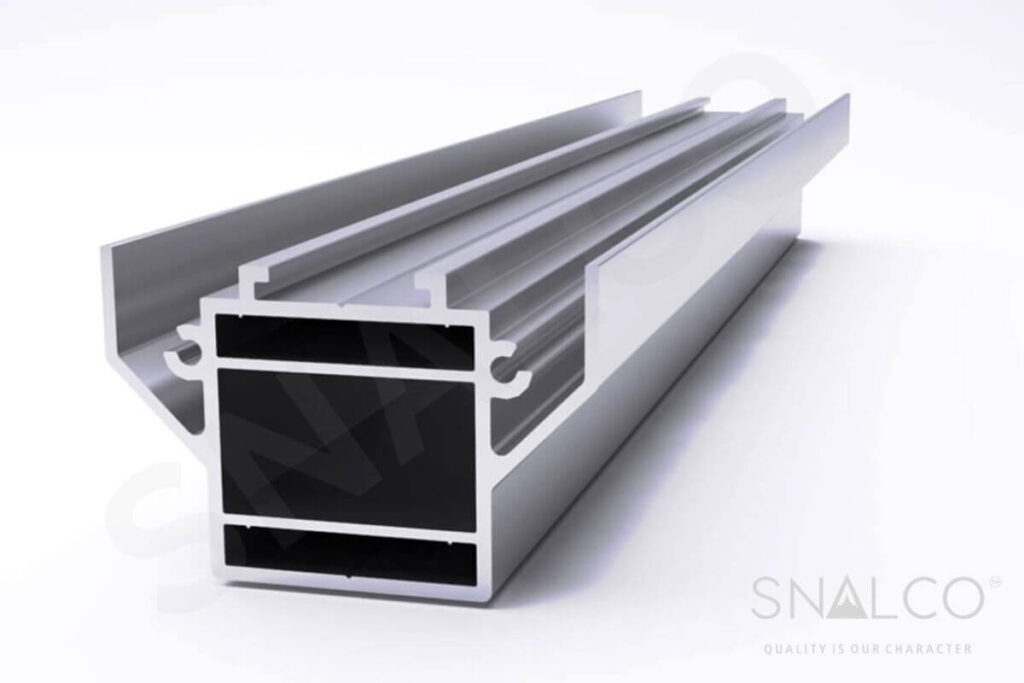

The Magic of the Extrusion Process by Snalco

How Aluminium Transforms into Architectural Marvels

The Process Breakdown:

- Billet Preparation: High-quality aluminium heated to precise temperatures

- Die Forcing: Material pushed through specialized shaping dies

- Cooling & Precision Cutting: Creating exact architectural sections

- Finishing: Surface treatments and final quality checks

Performance Characteristics That Wow

Aluminium Extrusion Superpowers:

- Exceptional strength-to-weight ratio

- Thermal efficiency

- Design flexibility

- Rapid installation capabilities

Applications Across Construction Landscapes offered by Snalco

Where Our Aluminium Extrusion Profiles Shine:

Versatile Usage Domains:

- Commercial building facades

- Residential structural components

- Industrial facility frameworks

- Infrastructure development

- Sustainable architectural designs

Our Precision Engineering Meets Design Innovation

Critical Design Considerations:

- Structural load requirements

- Thermal performance

- Aesthetic integration

- Long-term durability

- Cost-effective solutions

Sustainability: The Future of Construction Materials

Modern building and construction aluminium extrusion prioritizes:

- Recyclability: Up to 95% of aluminium can be recycled

- Energy Efficiency: Lower carbon footprint

- Longevity: Reduced replacement frequencies

- Minimal Waste Production

Technological Innovations by Snalco

We use Cutting-Edge Developments:

- Advanced computer-aided design (CAD) integration

- Precision die engineering

- Automated quality control systems

- Smart manufacturing technologies

The Economic and Environmental Impact taken in Consideration by Snalco

Aluminium extrusion isn’t just a manufacturing process – it’s a sustainable solution transforming how we conceptualize construction. By combining advanced engineering with environmental consciousness, this technology represents the future of architectural innovation and backed by the trust of Snalco for the commitment to the Green Environment.

Conclusion: Building Tomorrow’s World Today

Building and construction aluminium extrusion stands at the intersection of technological innovation, design flexibility, and sustainable development. As we continue pushing architectural boundaries, this remarkable process will undoubtedly play a pivotal role in shaping our built environment.