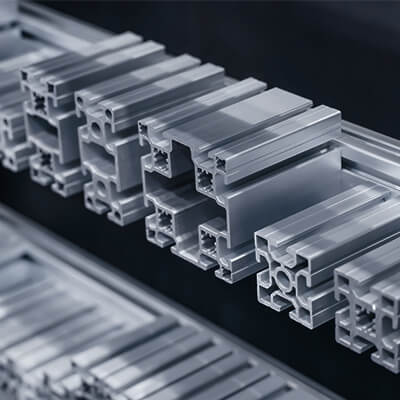

Snalco is proud to offer high-quality aluminium extrusion profiles for a variety of applications. As a leading manufacturer, we employ the latest extrusion technology and techniques to deliver strong, lightweight solutions to our customers.

We manufacture different types of Aluminium Extrusion Profiles used in many construction and engineering applications. Snalco has years of experience producing custom aluminium profiles for a wide range of industries based on our client requirements. We utilize our advanced production facilities and engineering expertise to manufacture extrusions that meet even the most demanding and complex design specifications.

How are Aluminium Extrusion Profiles Made?

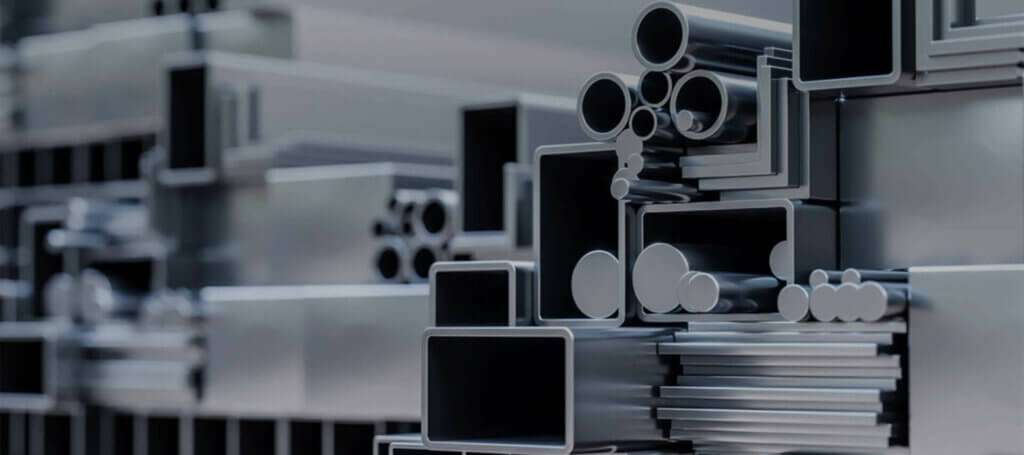

Aluminium extrusions begin as aluminium ingots that are heated to their plastic state in hydraulic presses. The hot aluminium is forced to flow through a preformed die opening, shaping it into the desired profile. As the aluminium exits the die, it cools and hardens into its final form.

The die opening can be designed with any cross-sectional shape, allowing aluminium extrusions to be customised for specific needs. Common extruded shapes include tubes, angles, channels, ‘I’ beams, and other structural geometries. By changing the die, unique designs can be produced cost-effectively.

Applications of Aluminium Extrusion Profiles

Aluminium extrusions are well-suited for applications that require lightweight and corrosion-resistant materials. Some common uses include:

Building and Construction

Window and door frames, curtain walls, structural framing for floors, roofs and walls.

Industrial Equipment

Machine guards, conduit, pneumatic and hydraulic cylinders.

The corrosion resistance and recyclability of aluminium extrusions make them a sustainable choice compared to other metals like steel. Their customisable shapes allow extrusions to be engineered for strength while minimising weight and material usage. With new profile designs, additional applications are being developed.

Transportation

Bicycle frames, lorry and trailer parts, aircraft components.

Advantages of Using Aluminium Extrusion Profiles

- Lightweight yet durable – Reduces material and transportation costs.

- Corrosion resistant – Minimises maintenance and extends product lifetime.

- Customisable – Enables unique designs without tooling charges like cast or machined parts.

- Recyclable – Aluminium extrusions can be melted down and reused indefinitely, promoting sustainability.

- Consistent quality – The extrusion process ensures uniform material density and mechanical properties.

- Variety of finishes – Anodised, powder coated or raw finishes provide aesthetic flexibility meeting various design requirements.

And SNALCO aluminium extrusion profiles offer a cost-effective structural material that can be engineered for strength, and corrosion resistance, and optimised for varied applications and conditions through customisable cross-sectional shapes.