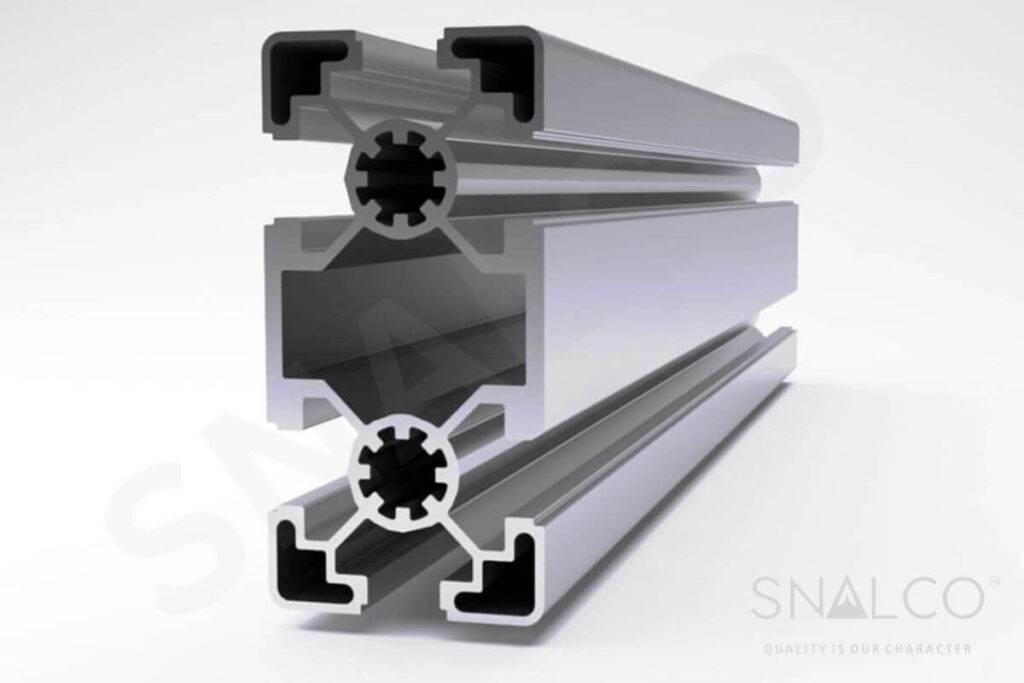

The Essence of Aluminium Extrusion in Fencing

Aluminium extrusion represents a critical manufacturing process that enables the creation of complex, high-performance fencing profiles with unparalleled efficiency. By pushing molten aluminium through precisely designed dies, and at SNALCO we can produce intricate fencing sections that offer remarkable durability, lightweight characteristics, and resistance to environmental challenges.

Key Advantages of Aluminium Fencing Sections by SNALCO

- Corrosion Resistance: Unlike traditional materials, aluminium naturally forms a protective oxide layer

- Lightweight Design: Enables easier installation and reduced structural stress

- Long-Term Performance: Maintains structural integrity with minimal maintenance requirements

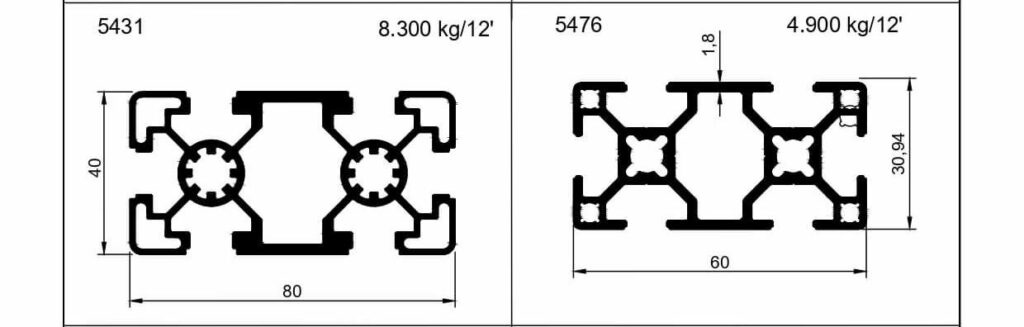

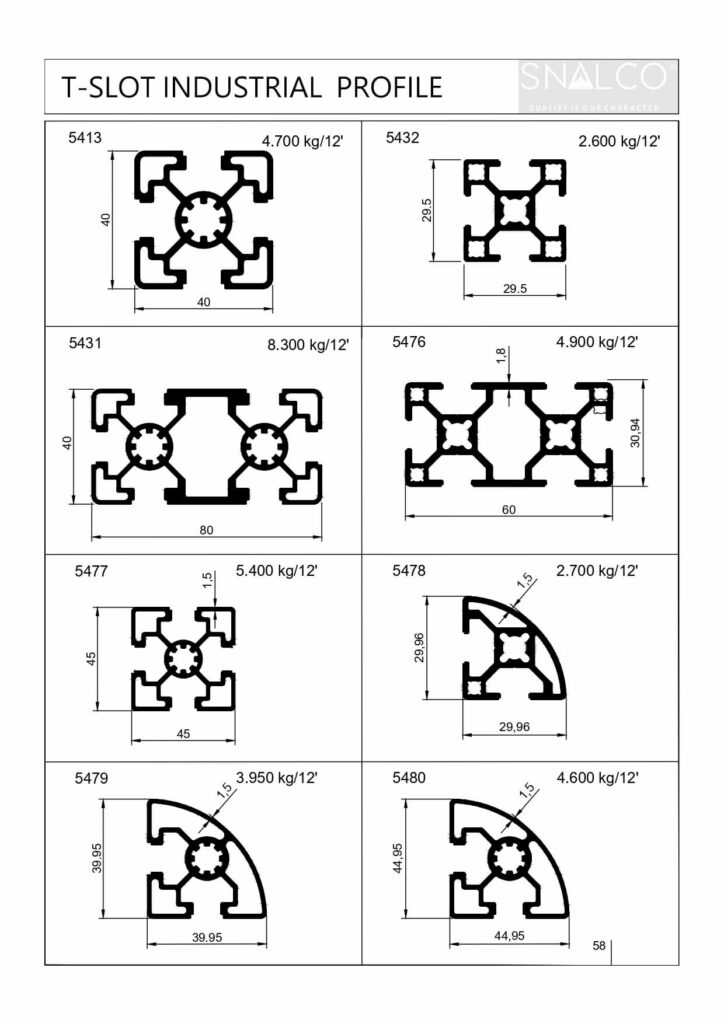

- Customization Potential: Allows for complex geometric designs and specific performance specifications

Manufacturing Excellence at SNALCO

Our approach to fencing section aluminium extrusion goes beyond standard manufacturing processes. We leverage advanced technological infrastructure to ensure each extrusion meets rigorous quality standards, providing our clients with solutions that combine aesthetic appeal and functional superiority.

Technological Innovation in Extrusion

The extrusion process at SNALCO involves:

- State-of-the-art die design

- Precision temperature control

- Advanced cooling techniques

- Comprehensive quality assurance protocols

Applications Across Industries

Aluminium extrusion for fencing sections is not limited to a single market segment. SNALCO’s products find applications in:

- Residential Fencing: Elegant, secure perimeter solutions

- Commercial Developments: Robust boundary demarcation

- Industrial Complexes: High-performance security barriers

- Agricultural Settings: Durable enclosure systems

Navigating Complex Design Requirements

SNALCO understands that each fencing project presents unique challenges. By offering customizable extrusion solutions, the company ensures that clients receive precisely engineered profiles that meet their specific technical and aesthetic requirements.

Collaborative Design Approach

Our team works closely with clients to:

- Analyze project specifications

- Develop tailored extrusion profiles

- Provide technical consultation

- Ensure optimal performance outcomes

Future of Aluminium Extrusion in Fencing

As technological advancements continue, SNALCO remains committed to pushing the boundaries of what’s possible in aluminium extrusion for fencing sections. Continuous investment in research and development ensures that our solutions remain at the forefront of industrial innovation.