Our comprehensive guide to the different types of aluminium extrusion profiles. Solid, hollow, and semi-hollow shapes explained. Aluminium extrusion is not ‘one size fits all’. Understanding the three main categories of profiles. Solid, Hollow, and Semi-Hollow, is crucial for selecting the right component for your engineering needs.

• Solid: Rods, bars, and angles (No enclosed voids)

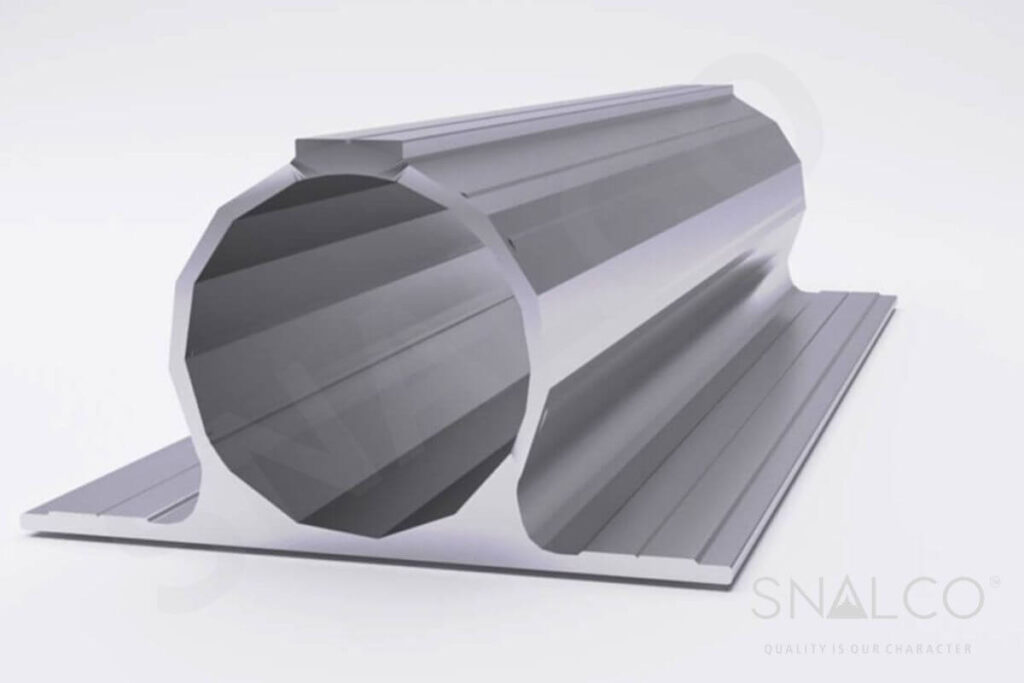

• Hollow: Tubes, box sections (One or more voids)

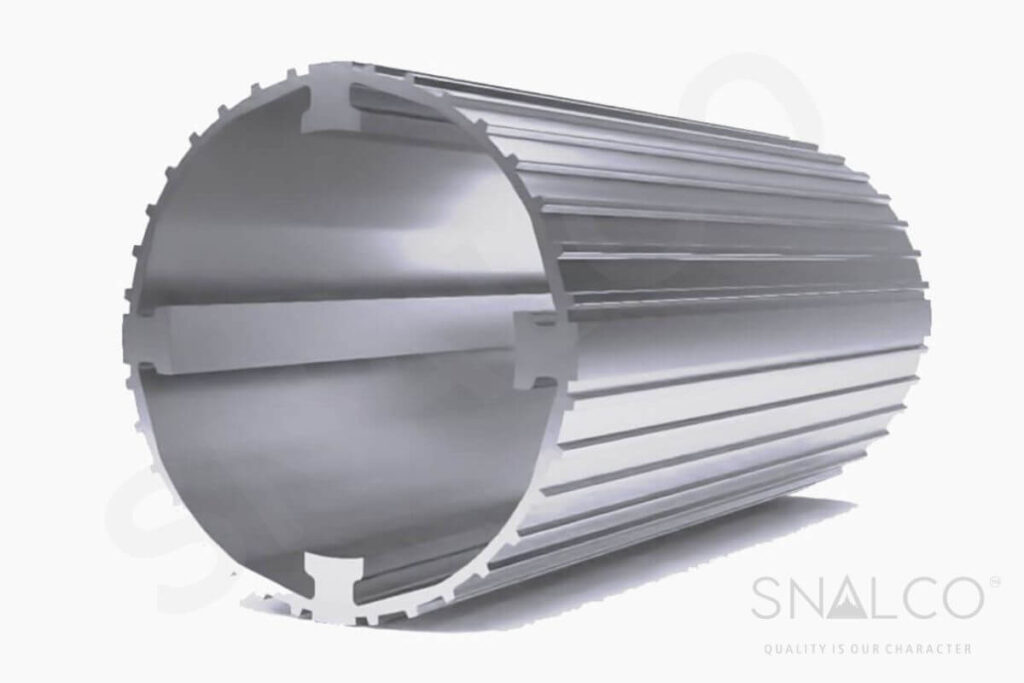

• Semi-Hollow: Channels with partially enclosed voids

Now, considering you have understood the basics of aluminium extrusion profiles, lets dive deeper.

Have you ever wondered what makes modern buildings, furniture, and solar panels so sturdy yet lightweight? The answer might surprise you – it’s aluminium extrusion profiles. These versatile metal components are everywhere around us, even though we might not notice them. Let’s explore what makes them so special and why they’re used in almost everything we see.

What Aluminium Extrusion Profiles offered by SNALCO?

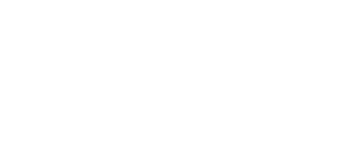

SNALCO aluminium extrusion profiles are long pieces of aluminium that come in different shapes and sizes. We create these profiles by pushing hot aluminium through special moulds – a process called extrusion. It’s similar to squeezing toothpaste out of a tube, but with metal at a very high temperature.

Common Types of Aluminium Extrusion Profiles Offered by SNALCO

| Profile Type | Common Uses | Key Features |

|---|---|---|

| T-Slot Profiles | Industrial frames, workstations | Easy assembly, modular |

| Structural Profiles | Building frameworks, heavy construction | High strength, large sizes |

| Architectural Profiles | Windows, doors, facades | Aesthetic finish, weather-resistant |

| Display Profiles | Exhibition stands, retail displays | Lightweight, decorative |

| Solar Mounting Profiles | Solar panel installation | Weather-proof, long-lasting |

Why Are Aluminium Extrusion Profiles So Popular?

Lightweight but Strong

Imagine carrying a steel beam versus an aluminium one. The aluminium beam would be much lighter but still incredibly strong! This makes it perfect for:

- Building windows and doors

- Creating office partitions

- Making solar panel frames

- Constructing display stands

- Building kitchen cabinets

Easy to Work With

Extruded aluminium profiles are like the Swiss Army knife of construction materials. They’re:

- Simple to cut and join together

- Easy to customize for different needs

- Available in many shapes and sizes

- Resistant to rust and corrosion

- Affordable compared to other materials

Different Types of Features

Surface Treatments

- Anodized – This makes them extra tough and colourful

- Powder coated – Adds a strong, coloured layer

- Natural finish – Keeps the original aluminium look

Where Can You Find our Aluminium Extrusion Profiles?

- Window frames in your house

- Solar panel mounting systems

- Office cubicle dividers

- Shopping mall displays

- Bus Body Structures

- Textile Structure

- Transmission Section

Finding the Right Aluminium Profiles

Whether you’re working on a school project or helping with home improvements, choosing the right aluminium profile is important. Consider:

- The weight it needs to support

- Where it will be used (indoors or outdoors)

- The look you want to achieve

- Your budget

- The size and shape needed

Connect with SNALCO

Interested in exploring how SNALCO can transform your project? Reach out to our expert team for personalized consultation and detailed project discussions.